Logistics operations hinge on precise control over goods movement and storage, where inefficiencies can disrupt supply chains and compromise delivery timelines. At the core of this control lies inventory management, a process that ensures stock levels align with demand while minimising errors in handling and tracking. As logistics providers face mounting pressures from fluctuating supply chains and the need for operational agility, integrating advanced tools like a warehouse management system becomes essential.

Understanding Inventory Management

Inventory management encompasses the systematic oversight of stock from receipt to dispatch, ensuring that goods are available when needed without excess accumulation. In logistics, where timely deliveries depend on efficient warehousing, effective inventory management prevents stockouts that could halt truckloading schedules or delay customer fulfilment.

Key Components of Inventory Management

At its foundation, inventory management involves tracking stock quantities, locations, and movements within a warehouse. This includes monitoring inbound shipments from suppliers via transport, assigning storage slots, and managing outbound orders for distribution. Without robust inventory management, warehouses risk inaccuracies such as misplaced items or overstocking, which erode operational efficiency.

Professionals in supply chain roles recognise that inventory management extends beyond mere counting; it integrates forecasting demand based on historical patterns and adjusting stock levels accordingly. For instance, in a distribution centre handling road-haulage goods, maintaining optimal inventory ensures that vehicles are loaded promptly, reducing idle times and enhancing throughput.

Challenges in Traditional Inventory Management

Manual approaches to inventory management often lead to human errors, such as incorrect data entry or overlooked stock rotations. In large-scale warehousing environments, these issues compound, resulting in inefficient space utilisation and slower response times to supply chain demands. Logistics firms increasingly seek solutions that automate these processes to achieve greater accuracy and speed.

The Role of Warehouse Management Systems

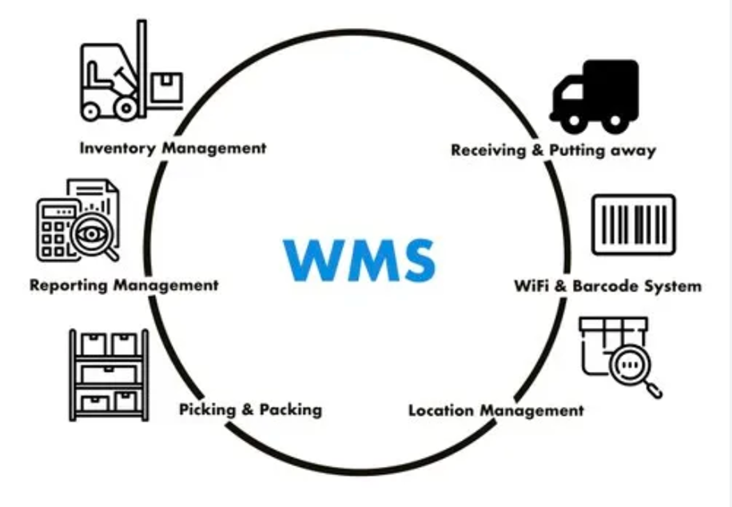

A warehouse management system (WMS) is specialised software designed to optimise warehouse operations, from inventory tracking to order processing. Unlike basic inventory tools, a warehouse management system provides real-time visibility into stock status, enabling seamless coordination in logistics networks.

Core Functions of a Warehouse Management System

A warehouse management system automates tasks such as barcode scanning for incoming goods, directing put-away processes, and generating picking lists for outbound shipments. By integrating with hardware like handheld scanners and conveyor systems, it ensures that warehouse staff execute tasks with precision, reducing the likelihood of errors in high-volume environments.

In practice, a warehouse management system serves as the central hub for data flow, connecting inventory management with broader supply chain activities. This integration allows logistics managers to monitor stock movements in real-time, facilitating quick adjustments to transport schedules and improving overall warehouse management.

How a WMS Enhances Inventory Management?

Implementing a warehouse management system transforms inventory management by introducing automation and analytics that address traditional shortcomings. Logistics companies adopting this technology report streamlined workflows, which directly support operational agility in competitive markets.

Automation of Tracking and Auditing

One primary way a warehouse management system boosts efficiency is through automated tracking. RFID tags and barcode systems linked to the WMS update inventory levels instantly upon receipt or dispatch, eliminating manual counts that are prone to discrepancies. In logistics, this means faster verification of loads for trucks, ensuring compliance with delivery windows.

Regular audits become effortless with a warehouse management system, as it generates reports on stock discrepancies or ageing inventory. This proactive approach to inventory management helps maintain accuracy, allowing warehouses to operate at peak efficiency without constant manual interventions.

Optimised Space and Resource Allocation

A warehouse management system employs algorithms to suggest optimal storage locations based on item velocity and size, maximising warehouse space. For inventory management, this translates to quicker retrieval times, as high-demand items are placed in accessible zones, supporting rapid order fulfilment in distribution centres.

Resource allocation benefits similarly; the system assigns tasks to staff based on workload and proximity, balancing labour distribution. In scenarios involving transport integration, this efficiency ensures that picking and packing align with vehicle arrival times, minimising delays.

Integration with Supply Chain Processes

Beyond standalone functions, a warehouse management system integrates with enterprise resource planning (ERP) tools, providing end-to-end visibility. This connectivity enhances inventory management by synchronising data across procurement, warehousing, and distribution, enabling logistics firms to respond swiftly to supply chain fluctuations.

For example, when supplier delays affect inbound shipments, the WMS can automatically adjust inventory forecasts and reorder points, maintaining stock balance without manual oversight.

| Aspect of Inventory Management | Manual Approach | WMS-Enabled Approach |

| Tracking Accuracy | Relies on periodic manual counts, leading to errors | Real-time updates via automation, ensuring precise data |

| Space Utilisation | Static assignments based on intuition | Dynamic slotting algorithms for optimal placement |

| Audit Frequency | Infrequent due to labour intensity | Automated, on-demand reports for continuous monitoring |

| Response to Demand Changes | Slow adjustments from manual reviews | Instant recalibrations through integrated analytics |

| Integration with Logistics | Disjointed, requiring separate coordination | Seamless data flow for aligned scheduling and loading |

This table illustrates the stark differences, underscoring how a warehouse management system elevates inventory management practices.

The Shift to 3PL Providers

Logistics companies are increasingly partnering with 3PL providers to outsource warehousing and distribution functions, allowing them to focus on core competencies like route optimisation. These providers bring specialised expertise in inventory management, leveraging scale to implement advanced systems that individual firms might find challenging to deploy independently.

By engaging 3PLs, businesses gain access to established networks that enhance supply chain efficiency. For instance, a 3PL can manage multiple clients’ inventories in shared warehouses, using pooled resources to achieve higher throughput. This model supports operational agility, as companies can scale warehousing needs without investing in fixed infrastructure.

Moreover, 3PL providers often incorporate cutting-edge warehouse management systems as standard, ensuring that clients benefit from the latest in technology integration. This partnership approach allows logistics firms to remain competitive by adapting quickly to market demands, such as varying volumes in transport.

Adopting Smart Logistics Management Practices

Smart logistics management represents the evolution of traditional practices through technology-driven strategies, emphasising connectivity and data utilisation. In the context of inventory management, it involves deploying IoT devices and AI within warehouses to predict and automate processes.

Adopting smart logistics management enables predictive maintenance of equipment, reducing downtime in warehouse operations. When combined with a warehouse management system, it provides actionable insights, such as alerting managers to potential stock imbalances before they impact deliveries.

Supply chain efficiency improves as smart practices facilitate better collaboration with suppliers and transporters. Real-time data sharing ensures that inventory management aligns with incoming shipments, minimising holding times and enhancing flow.

Summing Up

In competitive logistics sectors, smart logistics management fosters innovation, allowing firms to differentiate through superior service levels. By integrating warehouse management systems with smart tools, companies achieve greater visibility, enabling proactive decision-making that supports long-term agility.

The rise of 3PL partnerships and smart logistics management underscores a fundamental shift in logistics, where technology integration and outsourced expertise drive superior inventory management and warehouse management. These strategies equip organisations to navigate complex supply chains with precision, ensuring sustained competitiveness and operational excellence in an environment demanding unwavering efficiency.